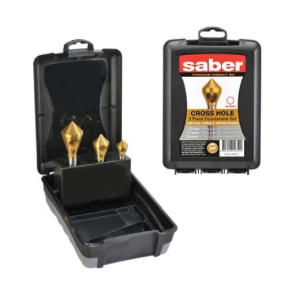

Saber HSS-Co5 (Cobalt) TiN Coated Cross Hole Round Shank 90 Deg. Countersink Set

Save 40%

Original price

$425.29

Original price

$425.29

-

Original price

$425.29

Original price

$425.29

Current price

$255.18

$255.18

-

$255.18

Current price

$255.18

- Saber HSS-Co5 (Cobalt) TiN Coated Cross Hole Round Shank 90 Deg. Countersink Set

- For countersinking and deburring in a wide range of materials including ferrous and non-ferrous metals.

- The intersection of the hole and cone form the cutting edge on the tool.

- The cone is not truly symmetrical as it is essential that the cone retreats away from the cutting edge as the tool rotates.

- If this does not occur the cutting edge will lack clearance and rub rather than bite into the material.

- This clearance is referred to as cutting relief.

- The radially relieved single cutting edge provides fast stock removal with low vibration for chatter-free operation ensuring the smoothest finish.

- These tools are best used as deburring tools, where a burr, or sharp edge, from a previous machining operation needs to be removed for cosmetic and safety reasons.

- They also may be used in softer materials (such as wood or plastic) to create a countersunk hole for a screw.

- HSS-Co5 (Cobalt) countersinks are extremely hard and provide superior performance and increased tool life especially in stainless steel and high tensile steel.

- Bronze Finish (gold oxide) surface treatment. The metallic brown coloured low temperature temper treatment is normally only used on cobalt tools for identification purposes.

- Gold Finish TiN Coating (Titanium Nitride) helps to dissipate heat and reduces friction and cold welding.

- The coating higher speed and feed rates can be achieved and tool life is greatly increased.

- The TiN coating is achieved by Physical Vapour Deposition (PVD).